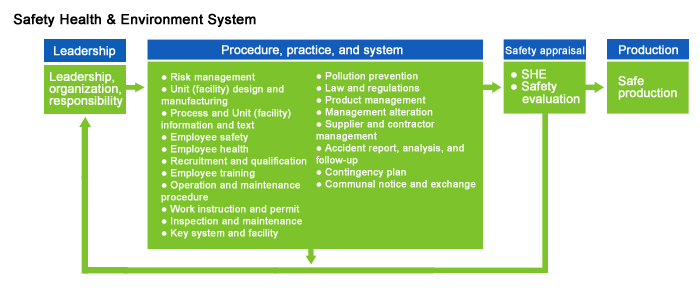

Bluestar has started with building a sound management system. It took in the successful mode and experience of its Qenos, and stuck to the existing GB/T28001 employee health, safety, management standard and the GB/T24001 environmental management standard and guidance. As a result, Bluestar brought into shape a distinctive Safety, Health, Environment system, or SHE for China’s chemical industry, paving the way for elevating the safety management in the future.

I. Improving the safety development system

China National Bluestar (Group) Co perfects its safety, health, and environmental protection (SHE) system

Bluestar has given priority to its SHE management system to improve its safety management over the long term and, in doing so, has borrowed advanced management techniques from the Australian company Qenos, which cover the whole safety, health, and environmental protection process. By the end of 2011, it had implemented the SHE system at several companies, such as the Bluestar New Chemical Materials Co’s Tianjin branch, and had helped raise the level of safety management at the companies. After BlueStar acquired Qenos, it used the Qenos SHE system to develop its own, with 20 parts and began applying the system at more than 30 subsidiaries. In 2010, it began implementing the 20 parts in three stages, the first of which had five of the elements — Leadership, promise, and responsibility; Employee safety; Work permits; Managing contractors; and Accident reporting, analysis, and tracking.

In applying these five elements, Bluestar was able to plug some management loopholes in leadership, visualization action, accident reporting, and analyzing the cause of problems and unified all documents on the five elements. For each of the elements, there were specific key performance indicators (KPI) to help collect data and analyze performance quality, and develop a closed management structure and increase safety awareness among leaders and employees and their work in operation management, contractor management and accident management.

II. Promoting green development

China National Chemical Corp safety supervision and inspection activities

Bluestar follows a principle of combining overall supervision and inspection with seasonal supervision and inspection, services, and employee participation. So, it held some hidden risk-detection activities and got all production team leaders and employees to take part, while it encouraged grassroots employees to report any minor accidents and risks, and used the lean six sigma method to analyze causes of minor accidents and learn a lesson from them.

Nanjing Bluestar New Chemical Materials Co conducts emergency drill

The Nanjing Bluestar New Chemical Materials Co held an emergency drill at the Nanjing Chemical Industry Park, on Nov 18, 2011, to deal with any possible production accidents. Organizers of the event were the National Workplace Emergency Management Center, the Jiangsu Work Safety Commission, and Nanjing government. The drill took into consideration the common occurrence and development of major chemical production accidents. Its main purpose was to test the ability of enterprises, industrial parks and the government to respond to and coping with such accidents. In commenting on the activity, Liu Tiemin, a member of the State Council’s emergency management group, said, “The setup was clear, the plan scientific, the response quick, and the commands orderly and we need to fully use this exemplary drill with a ripple-effect in promoting safety culture. This drill could even be an industry model both to learn from and to apply in emergency management.”

III. Protecting occupational health

In 2011, Bluestar paid greater attention to occupational health issues and improved related rules, took steps to improve equipment to protect workers’ health, and consolidated safety protection methods. It also organized annual checkups for workers, established employee health records, and got health insurance for employees. These things helped raise the level of worker safety and health, and lowered the incidence of occupational disease.

In a related move, the Shenyang Paraffin Chemical Industry Co’s CPP plant is promoting a “set menu” for training in facility checks. This consists of a “routine menu”, “nourishment menu” and “fun menu”. In the first, technicians explain inspection procedures and SHE identification of various risks to workers at the facility inspection site; in the second, there is specialized training for workers, in relation to their post and professional skills, which integrates theory with practice, and professional skills with safety skills; the third uses various activities to stimulate worker interest in and awareness of safety.

Nature and the environment are humans’ most important resource and Bluestar has always considered energy conservation, emissions reductions, and environmental protection priorities, and has a “zero emission and discharge” goal. By relying on environmental protection technology and innovative management, it tries to improve environmental protections, promote the low-carbon industry, and commit itself to “Resource-efficient, environmentally friendly” development and building a green, environmentally friendly corporate image.

IV. Developing science and technology for environmental protection

The chemical industry has traditionally been a heavy energy-consumer, heavy polluter, so, for improved management, energy conservation, emissions reductions, and lower costs, new technology and equipment R&D on environmental protection is very important to the industry. And the China National Chemical Corp continues to innovate in environmental protection technology and promote the application of new technologies, and has had some remarkable achievements in this area, as follows:

Largest osmosis membrane seawater desalination project

China’s largest seawater desalination project using an osmosis membrane method began operation at Caofeidianm, in Hebei province, in October 2011, in a Bluestar deal where the Hangzhou Water Treatment Technology Development Center handled the engineering. This was a pilot project with sponsorship from the National Development and Reform Commission. It has a 50,000-t/day water capacity and shows that Bluestar’s seawater desalination technology is among the world’s best.

Energy conservation and environmental protection in the service business

Bluestar has taken full advantage of its energy performance and chemical technology to move into new environmental protection business areas, such as energy performance contracting and energy conservation and emissions reduction auditing, to improve energy conservation and environmental protection ability in the chemical industry, for a winning situation, with an “I invest, you save energy, and everyone benefits” approach.

Bluestar has set up the Beijing Bluestar Energy Investment Management Co to provide professional energy-conservation services in the form of energy performance contracting. It uses its technology advantages for technological renovations and improved services for chemical companies in energy conservation and emissions reductions and has provided good environmental and economic benefits. The energy-conservation technology that Bluestar Energy Investment promotes include the following: membrane polar distance ion-exchange membrane electrolysis technology, with energy savings of 10-20 percent; oxygen-depleted cathode ion-exchange membrane electrolysis technology, with estimated energy savings of 20-40 percent; synthetic furnace technology where medium-pressure hydrochloric acid vapor is produced, with energy savings of 8-10 percent; and industrial steam boiler energy conservation technology with close to zero emissions, and energy conservation of 10 percent.